Scorziell Touches of Timber Framing

Here at Scorziell Development, Inc. we have been reviving styles from the art of timber frame construction. Mike Scorziell has studied old plans and techniques and in incorporating the technique that had been long neglected in our new homes.

A Few Facts About Timber Framing

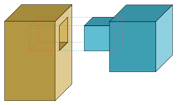

Timber framed structures differ from conventional wood framed buildings in several ways. Timber framing uses fewer, larger wooden members, commonly using timbers with dimensions in the range of 15 to 30 cm (6" to 12") as opposed to common wood framing which uses many more timbers with their dimensions usually in the 5 to 25 cm (2" to 10") range. The methods of fastening the frame members also differ, in conventional framing the members are joined using nails or other mechanical fasteners while timber framing uses mortice and tenon or more complex joints which are usually fastened using only wooden pegs.

Recently it has become common to surround the timber structure entirely in manufactured panels, such as Structural Insulating Panels. This method of enclosure means that the timbers can only be seen from inside the building, but has the benefits of being less complex to build and offering more efficient heat insulation. Structural Insulated Panels are a sandwich construction of two rigid composite materials usually wood based like OSB or plywood with a foamed insulating material in between either by gluing billets as in EPS (Expanded Polystyrene) or foamed and formed in place with polyurethane. The advantage of this for timber framing in the modern world is less of a dependency on bracing and auxiliary members like minor joists and rafters as the panels can span a considerable distance and greatly increase the stiffness of the timber frame itself.

Alternative ways include the use of straw bale construction. The straw bales are stacked for the walls with various finishes applied to the interior and exterior such as stucco and plaster. This appeals to the traditionalist and the environmentalist as this is using "found" materials to build.

Advantages

The use of timber framing in buildings offers various aesthetic and structural benefits, as the timber frame lends itself to open plan designs and allows for complete enclosure in effective insulation for energy efficiency.

The timber frame structure goes up quickly in its modern incarnation. While some modern shops still cut the timbers with hand tools and hand guided power tools, modern computerized numeric control (CNC) machinery has been readily adapted to the task. This eliminates much of the repetitive labor from the process, but still often requires hand-finishing; most notably, the complexity of hip/valley joinery as of yet cannot be duplicated by CNC machinery beyond simple cuts. Additionally, due to the rigid timber requirements of CNC machinery, odd sized, tree trunk, hand hewn, and recycled timbers are usually hand cut even in the machine dominated shops.

One aid in speeding up assembly on site is prefitting the frame, usually in bent or wall sections that are laid out on the shop floor. This can assure a correct fit and with predrilling for the pegs it speeds the site process. This pre-fitting in the shop is independent of a machine or hand cut system. Valley and Hip timbers usually are not prefit but careful layout and checking can catch most errors.

Quite literally in 2-3 days an average size timber frame home can be erected and within a week to 2 weeks after that the shell of the house is ready for "drying in", which is to say ready for windows, mechanical, and roofing. The shell in this case would be with SIP or Structural Insulated Panels.

The timber frame can give the home owner the ability to make a creative statement through the use of design and specialty touches like carvings of favorite quotes and incorporating timbers from heirloom structures, like a barn from a family homestead.

Disadvantages

Because the structure is made from wood, it inherits any disadvantages wood may exhibit as an engineering material. Some possible disadvantages of wood as opposed to some other building materials include:

- Noise from footsteps in adjacent rooms both above, below and on the same floor in such buildings can be quite audible.

- The possibility of infestation by insects.

- Various types of rot in both wet and dry conditions, the latter of which is specifically called dry rot.

- Wood burns more readily than some other materials, making timber frame buildings somewhat more susceptible to fire damage, although this idea is not universally accepted: Since the cross-sectional dimensions of many structural members exceed 15 cm × 15 cm (6" × 6"), timber frame structures benefit from the unique properties of large timbers, which char on the outside forming an insulated layer that protects the rest of the beam from burning.